QUE HÀN ESAB OK 74.78

Mã sản phẩm: E9018-D1-2.5

Giá gốc 0₫

OK 74.78 là que hàn hồ quang tay độ ẩm thấp (LMA) thích hợp để hàn thép độ bền cao sử dụng trong các ứng dụng nhiệt độ thấp. Độ dai va đập tốt khi nhiệt độ xuống đến -40 ° C. Rất thích hợp cho cả hàn hồ quang bao bọc "enclosed welding" và hàn đắp đường ray, khi yêu cầu độ cứng khoảng 250 HV. Độ ẩm của vỏ bọc que hàn rất thấp, điều này làm cho OK 74,78 phù hợp trong các trường hợp khi không thể nung nóng que trước khi hàn.

ESAB là thương hiệu hàng đầu về hàn - cắt kim loại lâu đời, nổi tiếng trên toàn cầu.

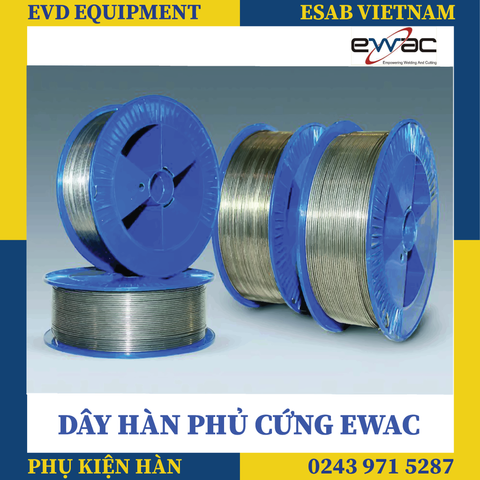

🔖 ESAB với công nghệ tiên phong trong lĩnh vực hàn kim loại đã nghiên cứu và cho ra đời những dòng máy hàn mạnh mẽ, công suất lớn, hiệu suất làm việc cao. Cùng các dòng Vật liệu hàn: dây hàn, que hàn, thuốc hàn...đa dạng, phong phú phục vụ cho nhiều mục đích sửa chữa, xây lắp, đắp cứng, chống mài mòn.

🔖 Que hàn TIG - Que hàn TIGROD - Que hàn ESAB - Que hàn OK - Que hàn nhập khẩu. Que hàn chất lượng cao - Que hàn giá tốt - Que hàn đặc chủng.

☎️ Công ty TNHH EVD Thiết bị và Phát triển chất lượng là đại diện phân phối chính hãng thiết bị và vật liệu hàn ESAB từ năm 1993. Liên hệ với chúng tôi để được tư vấn lựa chọn sản phẩm phù hợp nhu cầu của bạn.

☎️ ☎️ ☎️ 08 66 11 22 36

Typical Tensile Properties

| ISO As welded | ||||

| Elongation | Tensile Strength | Yield Strength | Stress Relieved Temperature | Stress Relieved Testing Time |

| 24 % | 650 MPa | 600 MPa | - | - |

| AWS Stress relieved | ||||

| Elongation | Tensile Strength | Yield Strength | Stress Relieved Temperature | Stress Relieved Testing Time |

| - | - | - | 620 °C | 1 hr |

Typical Charpy V-Notch Properties

| ISO As welded | |||

| Impact Value | Testing Temperature | Stress Relieved Testing Temp | Stress Relieved Testing Time |

| 90 J | -40 °C | - | - |

| 70 J | -50 °C | - | - |

| AWS Stress relieved | |||

| Impact Value | Testing Temperature | Stress Relieved Testing Temp | Stress Relieved Testing Time |

| - | -50 °C | 620 °C | 1 hr |

Typical Weld Metal Analysis %

| Mn | Mo | C | Si | Ni | Cr |

| 1.60 % | 0.35 % | 0.05 % | 0.35 % | 0.03 % | 0.03 % |

Deposition Data

| Diameter | Current | Deposition Rate | Fusion time per electrode at 90% I max | kg weld metal/kg electrodes | Number of electrodes/kg weld metal | Voltage |

| 6.0 x 450 mm | 240-340 A | 3.6 kg/h | 103 sec | 0.69 kg | 10 | 24 V |

| 2.5 x 350 mm | 75-100 A | 0.90 kg/h | 55 sec | 0.62 kg | 73.0 | 22 V |

| 3.2 x 450 mm | 105-140 A | 1.30 kg/h | 86 sec | 0.65 kg | 32.0 | 23 V |

| 5.0 x 450 mm | 190-260 A | 2.60 kg/h | 100 sec | 0.68 kg | 14.0 | 24 V |

| 4.0 x 450 mm | 140-190 A | 1.80 kg/h | 97 sec | 0.65 kg | 20.5 | 23 V |

| Approvals: | ABS, 3Y H5, CE, EN 13479, DB, 82.039.02, DNV-GL, 3 Y46H5, VdTÜV, 01027 |

| Classifications: | SFA/AWS A5.5, E9018-D1, EN ISO 18275-A, E 55 4 MnMo B 3 2 H5 |

Approvals are based on factory location. Please contact ESAB for more information.

| Alloy Type: | Low alloyed (0.4 % Mo) |

| Coating Type: | IMPERIAL_Basic covering |

| Diffusible Hydrogen: | < 5.0 ml/100g |

| Welding Current: | AC, DC+ |