DÂY HÀN ESAB - OK AUTROD 12.51

Mã sản phẩm: ER70S-6-1.2

Giá gốc 0₫

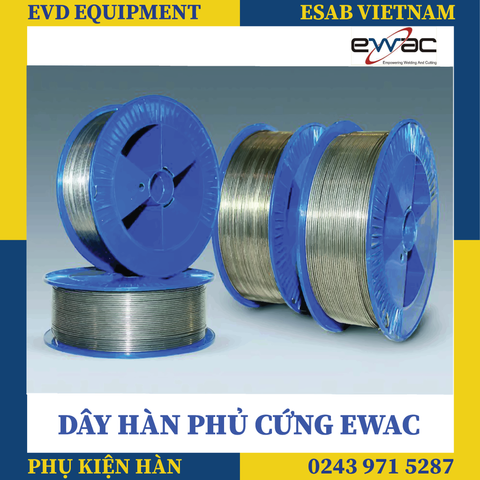

OK Autrod 12.51 là dây hàn thể rắn được bọc đồng.Hàm lượng cao của các chất khử có trong dây hàn cho phép hàn kể cả khi trên bề mặt chi tiết có nhiều bụi bẩn, rỉ sét đồng thời tạo tính chảy loãng và hình dạng mối hàn tốt hơn.

ESAB là thương hiệu hàng đầu về hàn - cắt kim loại lâu đời, nổi tiếng trên toàn cầu.

🔖 ESAB với công nghệ tiên phong trong lĩnh vực hàn kim loại đã nghiên cứu và cho ra đời những dòng máy hàn mạnh mẽ, công suất lớn, hiệu suất làm việc cao. Cùng các dòng Vật liệu hàn: dây hàn, que hàn, thuốc hàn...đa dạng, phong phú phục vụ cho nhiều mục đích sửa chữa, xây lắp, đắp cứng, chống mài mòn.

🔖 Dây hàn ESAB - Dây hàn nhập khẩu - Dây hàn lõi thuốc - Dây hàn chất lượng cao - Dây hàn giá tốt - Dây hàn đặc chủng.

☎️ Công ty TNHH EVD Thiết bị và Phát triển chất lượng là đại diện phân phối chính hãng thiết bị và vật liệu hàn ESAB từ năm 1993. Liên hệ với chúng tôi để được tư vấn lựa chọn sản phẩm phù hợp nhu cầu của bạn.

☎️ ☎️ ☎️ 08 66 11 22 36

Typical Tensile Properties

| AWS CO2 (C1) As welded | ||||

| Elongation | Tensile Strength | Yield Strength | Stress Relieved Temperature | Stress Relieved Testing Time |

| 30 % | 530 MPa | 430 MPa | - | - |

| EN 80Ar/20CO2 (M21) As welded | ||||

| Elongation | Tensile Strength | Yield Strength | Stress Relieved Temperature | Stress Relieved Testing Time |

| 26 % | 560 MPa | 460 MPa | - | - |

| EN 80Ar/20CO2 (M21) Stress relieved | ||||

| Elongation | Tensile Strength | Yield Strength | Stress Relieved Temperature | Stress Relieved Testing Time |

| 28 % | 495 MPa | 370 MPa | 620 °C | 15 hr |

| EN CO2 (C1) As welded | ||||

| Elongation | Tensile Strength | Yield Strength | Stress Relieved Temperature | Stress Relieved Testing Time |

| 25 % | 540 MPa | 440 MPa | - | - |

Typical Charpy V-Notch Properties

| AWS CO2 (C1) As welded | |||

| Impact Value | Testing Temperature | Stress Relieved Testing Temp | Stress Relieved Testing Time |

| 75 J | -30 °C | - | - |

| EN 80Ar/20CO2 (M21) As welded | |||

| Impact Value | Testing Temperature | Stress Relieved Testing Temp | Stress Relieved Testing Time |

| 130 J | 20 °C | - | - |

| 120 J | -20 °C | - | - |

| 100 J | -30 °C | - | - |

| 90 J | -40 °C | - | - |

| EN 80Ar/20CO2 (M21) Stress relieved | |||

| Impact Value | Testing Temperature | Stress Relieved Testing Temp | Stress Relieved Testing Time |

| 120 J | 20 °C | 620 °C | 15 hr |

| 90 J | -20 °C | 620 °C | 15 hr |

| EN CO2 (C1) As welded | |||

| Impact Value | Testing Temperature | Stress Relieved Testing Temp | Stress Relieved Testing Time |

| 110 J | 20 °C | - | - |

| 75 J | -30 °C | - | - |

Typical Weld Metal Analysis %

| Mn | C | Si |

| 1.46 % | 0.078 % | 0.85 % |

Deposition Data

| Diameter | Current | Deposition Rate | Voltage | Wire Feed Speed |

| 0.6 mm | 30-100 A | 0.7-1.7 kg/h | 15-20 V | 5.5-13 m/min |

| 1.0 mm | 80-300 A | 1.0-5.5 kg/h | 18-32 V | 2.7-15 m/min |

| 1.32 mm | 130-400 A | 1.5-8.5 kg/h | 19-35 V | 2.4-15 m/min |

| 1.4 mm | 150-420 A | 1.6-8.7 kg/h | 22-36 V | 2.3-12 m/min |

| 1.2 mm | 120-380 A | 1.3-8.0 kg/h | 18-35 V | 2.5-15 m/min |

| 1.6 mm | 225-550 A | 2.1-9.4 kg/h | 28-38 V | 2.3-10 m/min |

| 1.14 mm | 100-350 A | 1.2-7.0 kg/h | 18-34 V | 2.6-15 m/min |

| 0.8 mm | 60-200 A | 0.8-2.3 kg/h | 18-24 V | 3.2-10 m/min |

| 2.0 mm | 300-650 A | 4.4-10.2 kg/h | 32-44 V | 3.0-7 m/min |

| 0.9 mm | 70-250 A | 0.9-3.5 kg/h | 18-26 V | 3.0-12 m/min |

| Approvals: | ABS, 3YSA, BV, SA3YM, CE, EN 13479, DB, 42.039.06, DNV-GL, III YMS, LR, 3YS H15, PRS, 3YS, RS, 3YMS, VdTÜV, 00899, CWB, B-G 49A 3 C1 S6 (B-G 49A 3 C G6), PV,ZG, JIS, YGW12, ZG, NAKS/HAKC, 0.8-2.0 mm, PV, NAKS/HAKC, 1.2-1.6 mm, ZG, RINA, 3YS, PV,ZG |

| Classifications: | EN ISO 14341-A, G 38 3 C1 3Si1, Weld Metal, EN ISO 14341-A, G 42 4 M20 3Si1, Weld Metal, EN ISO 14341-A, G 42 4 M21 3Si1, Weld Metal, EN ISO 14341-A, G 3Si1, Wire Electrode, SFA/AWS A5.18, ER70S-6, Wire Electrode, CAN/CSA-ISO 14341, B-G 49A 3 C1 S6, Wire Electrode, JIS Z 3312, YGW 12(C1), Wire Electrode |

Approvals are based on factory location. Please contact ESAB for more information.

| Alloy Type: | Carbon-manganese steel (Mn/Si-alloyed) |

Extra Information

*APPROVAL COMMENT

Approval valid for lot numbers with prefix in right column.